Summer 2024

Ready for initial testing! Browse the

User Manual

Kitchen counter is being populated with clutter!

L-R: Ice box, Sink, Stove

Note the under counter LED lights.

East wall shelf and blue accent, 12 Volt receptacle

West wall

Fold down table and DC plug above, shelf with blue accent, firewood box,

wood stove

Kitchen counter, Left end with drop-in ice box

Separett Waterless Composting Toilet

Signs tell users to turn on the vent fan (under far kitchen cabint) and

be sure to observe the sit-down design.

LED lighting and fan complete this compact bathroom.

Fold-down table on West wall

12 Volt receptacle above

Kitchen Counter across the south

wall.

Valhalla Cherry stained and home-built cabinets.

Appliances installed

Electrical corner

Six switches for various lighting schemes. Green light indicates main

power is on.

USB outlet above, main power switch and and battery bank in cabinet

below.

Cubby in that back corner is still under consideration.

View photo of fuse block and

wiring behind the panel

Roughing in in the composting toilet/bathroom

Kitchen cabinets installed and ready

for fit check of appliances.

Electrical corner far right. We used nearly a whole 500' roll of wire. View a

circuits list.

Tankless water heater mounted on a

post behind the building.

It will soon have a weatherproof box around it.

Initial mounting was on the back of

the building but it caught fire during testing and nearly enveloped

the entire back wall. see photo

of the burned unit.

Shower stall with drain behind

building

We will build a box for it in the next few weeks.

Hot and cold pex water lines run inside separate sealed conduits six

feet to the building.

Propane gas line is the yellow pipe and us certified direct bury.

The Ebay seller quickly sent a replacement. Infiltration box has a drain

that connects to the grey water piping.

Final hookup of

Separett waterless composting

toilet.

A small fan dries the solid waste and exhausts through the pipe to the

outside.

Composting toilet with top open

Urine is directed out through the building's grey water system to a

rockpit.

Solid waste goes in a compostable bag in the black bucket which rotates 3 degrees every time

one sit on the seat. The bucket holds 30 days of wasteand is dried

by the fan.

This is a mandatory sit-down toilet for all users!

Taylor installing the loft east wall.

We used high quality 1/4 plywood with natural stain/sealer for all

interior walls

Trying out the

shortwave antenna installation

West interior cedar

ceiling finished

Wood stove in foreground, chimney pipe between windows

Fitting the cedar lapped boards around the 2x8 loft beams.

Cedar was excess leftover siding from the

prow house.

Beams are rough cut from trees on the property.

View photo of raw lumber arriving

from the sawmill down the road.

Fitting around the chimney box

West loft wall

Red wire top center is for an LED "up" light to "wash" the ceiling

at night

Here's Taylor

cutting some ceiling boards.

New ATT cell tower in

upper left provided nearly 50% of the materials for this project.

North wall with 12V

outlet and bathroom

Tailgate Breakfast prepared on scrap

cedar plank provided protein for a morning's work.

...another shot of that

exceptional breakfast

West wall plywood lower wall

installation

We chonse

1/4" plywood stained natural and sealed

That black box is the CO/LPG (carbon monoxide/propane gas)

monitor/alarm.

Box to the right is the ham radio

antenna connection

White plate above is a standard 12V cigar lighter connection.

Installing the kitchen cabinet

modules and facing Summer 2023.

View the modules being fabbed

in the valhalla wood shop

Facing wood is Cherry from a large tree on the property milled at Paul

Von Steubbe's mill

We processed the rough cut boards in the

Valhalla woodshop

Installing the drawers

View a sketch we drew to work from

Finishing the flagstone stove base

July 2023

We bought the flagstones from "Simply

Rocks"

Here's Taylor gluing the pieces to

the hardiboard base

Finished base ready for stovepipe

hookup

Trim Paint Complete 6/9/23 It rained!

Here's Ylber from

Dream Team Painting working

on the front trim and soffits.

Youness working

South side trim

Our friend Ylber paying close

attention to detail.

Note all joints have been sealed.

Youness on the ladder.

Note the insulator for the ham radio antenna (top center)

11/18/22

Installing R30 Insulation in the joist spaces.

Kitchen will go against the wall far left.

We light the stove and in a few minutes the room heats up to a nice

glow.

This is going to be a nice little cabin.

Another shot of the insulation going

in. That's friend Grier doing the work here.

Note the 12 Volt lighter socket above his left hand.

Helper Brandon looking down from the

loft during insulation install.

We are getting set to drill 2" cross ventilation holes at the top of the

rafters.

Note the LED "up lights" temp installed

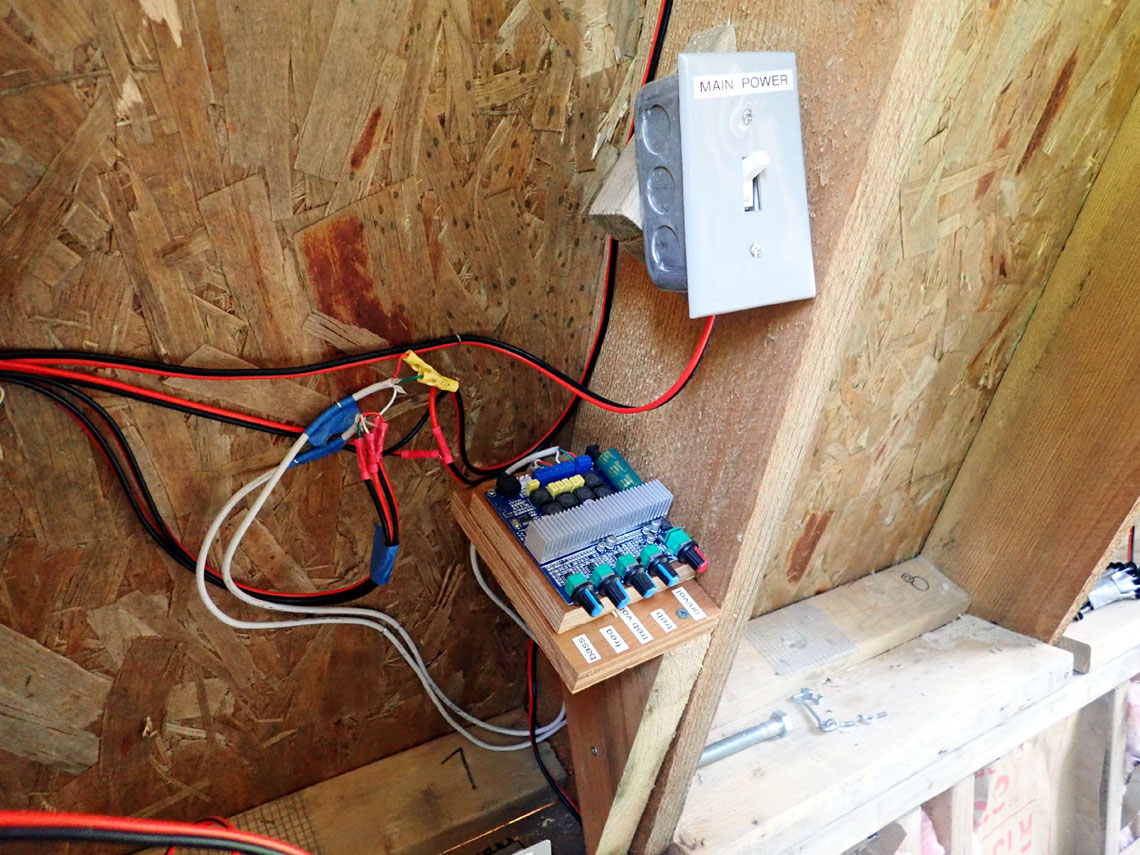

Electrical corner with fuse block,

solar controller and three temp switches..

On the right is the building master power switch and the Bluetooth

stereo amp

We built temporary - but sturdy

scaffolding to make it safer to work at waist/chest heights.

Every possible opening has a window!

View the sketch we used to order

the windows from Lund Glass

Todd Lund worked with us to make sure we got exactly what we wanted.

Note the sturdy pony wall repurposed from the nearby

cell tower construction

It took a lot of fooling around with

the compound angles.

view a sketch of the design

we used to hold the double pane glass in place.

Window Installation!

L-R Grier, Taylor

Three friends helping to get the

exterior window blocking and seal complete before the end of October. Note the full-size 10" Makita compound miter

saw, center right.

That thing ran on four Makita rechargeable batteries!

A late "change order"

Carpenters hate these but we designed the loft too

small.

It needed to be 80" deep to accommodate tall people and to add some

extra room. The other change was to add two LED "wash lights" to flood

the upper ceiling with light to add a spacious feel to the A-Frame at

night.

Cold water plumbing , demand pump and

grey water drain to rockpit.

View a sketch we worked

from to build the hot and cold piping

Separett Villa 9215

12Volt power in the blue box to the compost toilet. There's a small fan

that runs 24/7 and dries the solid material. Water goes down and out the

grey water drain.

Top 3.5" vent goes up 4' and out the back wall.

Separett website

Kitchen LED fixtures found on EBay

Six "cool-white" mounted in the main room ceiling under the loft.

From the

"12 volt online" store

You hit the little button and hold it

down and it dims to where you want.

Plus, when you turn it off and back on, it remembers the setting.

This is a temporary mounting scheme until we are ready to design

the finished ceiling.

Working on the Back Wall

Shakes and window trim August 2022

Shakes were repurposed from the

homestead house

Taylor helping to finish it up

I

I

Making and installing the cedar facing for the

windows

Pair of 100W

Renogy solar panels

facing west

View a shot of the one panel on

the south side, it gets morning sun.

Chimney installation

August 2022

Working on the cedar facing for the windows

A-Frame collar ties and loft window

Kitchen and electrical corner

Note the "high-end" Advent "Calypso" 2 way speaker top center (R ch)

A few temp circuits were set up to use the stereo and try out the lights

Sunny July workday

Wood Stove in Left foreground with pipe straight up

40W Bluetooth Amplifier and main power

switch

Temporarily mounted for some tunes while working.

July 2022

Telephoto shot of Jose and Luis

They

put up the roofing in one day

Looking north

A step off to the 12x12 deck

Spring 2022

Building the deck

(L-R) Grier, Tyler

Note the metal Folgers coffee can of nails

We got a great deal on an odd lot of

composite decking.

The width was determined by that old "bistro" table and chairs.

These

granite boulders made a great base for the deck.

A geologist told us the the whole huckleberry hill is an ancient granite

"uplift". It is not the same kind of rock as the mountain in the

background.

Everything was nailed just after this photo was taken

We decide that we need a

small deck along the West side.

This was to allow access to the shower and utilities along the back wall

The deck would also provide a safe ladder base for the upcoming chimney

and roof install. Using a power chisel to flatten the

top of two granite boulders

Preparing the North corner for the

stove installation

Here's the corner where the fuse box,

solar controller and battery bank will reside.

Each wire is numbered as to where it goes on the wall chart.

Wiring the cabin for 12 Volts

View close up of that box with Ham Radio

coax cable

We install an insulated floor.

This is like bubble wrap with aluminized Mylar on each side

New sub floor nailed over the insulation.

Fall 2021

We cover the roof with 10mil black

plastic

(L-R) Sage, Grier and Blaine (on interior ladder)

Getting the last pieces of the roof

nailed in place.

Its beginning to rain..

Interior looking out the roughed-in

front door opening

Note the heavy-duty pony wall salvaged from the cell tower concrete

forms.

Working on the West side

All the OSB and pony wall materials salvaged from the new

ATT cell tower

leftovers.

Finishing the last of the OSB

roof, 10/31/21

It is beginning to rain. Generator is under the little roof.

This was a

tough roof to cover due to the 67 degree angle

All the OSB was salvaged from the new ATT cell tower.

L-R Blaine, Grier

More about:

Oriented

Strand Board

Nice late afternoon shot

Note the large 36"x 60" back window

(L-R) Blaine, Grier

October 14th: Setting the front wall

vertical member

Setting the horizontal divider for the upper triangular windows

View a shot of how we determined

the optimum A-Frame window angles

Nice shot of the rough framing

progress on the front wall.

Note the single entry door on the left and four upper triangular

windows

Rough framing of the rear loft

window

See what the sill height

looked like from the inside

Framing the bathroom wall.

Note the 36x60 back window opening

The loft only occupies the back half of the cabin.

The 3' cell tower forms

made an easy pony wall

October 5th: Adding additional

blocking at bottom of each A Frame

We had a meeting to discuss how much bottom strengthening was enough.

Here's Blaine firing three 6d nails

up into the bottom of each frame

Safety monitor talked to him about wearing safety glasses

Nice shot down the upper part of the

A Frame, angle is 67 degrees

Whoops looks like that second

collar tie is crooked

Rear of cabin showing 14' 2x8 nailed

on bottom of the frames

This will securely hold the additional frame at each end. Dog Sage

checking for accuracy.

Scheme to reinforce and hold

the 12" extensions on each end

Telephoto shot from bottom of hill

showing the new 12" extensions

October 4 2021

Tying the all the A Frame bottoms together for the 12" extension on each end

Jan checking out the temporary loft.. She's pretty impressed!

Note the upper structural pieces, collar ties, blocking and 1x6 tie

boards.

All framing from Valhalla wood.

Double door on front is framed in

[ Later changed to single door on left ]

Temporary Loft plywood in background

Wood stove destined for RH front corner

Finishing up the day on September

22nd 2021

(L-R) Grier, Roman

Here's Dave checking to see how much

room there's going to be in the loft

It feels a lot roomier without a roof!

Roman working on the front

rough-in

Adding 2x8 spacers

We finalized the loft rafter height

and Grier fastening to A Frame

Loft will encompass only the back

half of the cabin

Decided to lower the back ceiling: 7' 2" to floor

Building the third

frame on the adjacent 12x12 cedar deck

Note the pre-cut top triangles on right

Here's Jan mounting the second course

of shakes on the south side

Pony walls covered with tarpaper

On left, cut and stacked repurposed cedar shakes from the original

homestead house ready to be

installed

Two "A"s set and

temporarily braced

Assembling the first A

Here's Grier and Brandon making the measurement for the collar tie

location

3/4" plywood on each side of the top

All the frames cut

and stacked

Note all the OSB plywood stacked on the right

Cell tower contractor donated these

huge crates from the tower assembly materials

View photo of the crates

full of fake branches being mounted to the tower

We disassembled at the tower site and hauled directly to our

construction area.

All of the 4x8 OSB plywood will be used for the roof

Using the first frame as a template

to cut the remaining birds beaks and end trim

Nice rough cut beams from Paul VonSteubbe's

sawmill down the road.

View the trailer load of logs on

its way to the mill.

One last check to finalize our design

Note the top angles are cut and a temporary tie-piece

Loft joist set for 7' ceiling to gain as much loft-space as possible

Loft will only cover the back half of this tiny house

Final centering test

Plumb-bob dropped from top to center of floor pencil mark shows we are

3/4" off!

Brown floor at bottom of photo is the front edge of the A-Frame

Top of photo is the 12x12 adjacent/independent cedar deck.

Note poor choice of polyurethane/stain after two yrs of weather.

Loft joist level check for clarity

and marking of cut lines

Note bottom edges of the A-Frame rafters are set to mark the "birds

beak" cut lines. This frame will be the template for the remaining seven

frames

Here's the dream A Frame we found on

the internet

Final setting for the angle of the

"A"

Left it this way for a week to look

at it: 67 degrees.

Fooling around with the right angle

for the A

This is the first iteration

Second iteration

We went with this one

We mounted and then braced the

initial A

Next, we finalized the angles and scribed a "birds beak" for the frame

to sit on the pony wall.

The first "A" will be a template for the next six.

Estimating how much room the loft

will have with this angle.

Requirements were: you have to be able to stand up and get in and out of

bed!

View the reference sketch paper on

table

Trimming some 18'x8" rough-cut

Valhalla lumber for the main roof joists.

These are 18' 2x8 lumber rough-cut from leftover logs from the tree farm

2018/2019 logging and thinning

project

Laying out the

initial A-Frame dimensions on the adjacent 12x12 deck

We braced the open sidewalls for safety

Painted the sub floor with some

leftover Valhalla "brown"

This should keep the plywood intact until the roof is complete.

View an early sketch

developing the A-Frame idea

Chance availability of cell tower

3'x8' concrete forms.

Allowed us to build an easy pony wall for the A-Frame.

View a later sketch

developing the A-Frame structure.

We disassemble some of the the 3'x8'

ft concrete forms and retain the 2x6's and 3/4 plywood.

Here's Grier from urban

frontier making quick work of the sub floor

Picking up a few of the concrete forms from the new

ATT cell tower

Second 12x12 deck ready for an idea

Developing an idea of what we

could do with 12x12

We added a second deck for a possible future

cabin/tiny house

This site faces NW

Little roof on right covers your firewood or your cooler

2019

We just thought this was an excellent place for a campsite.

Here's the basics

The hill and platform make a great spot to enjoy the

acres of woods, creek, ponds and trails

Cedar 5/4 decking: main platform

Wide shot of huckleberry hill

Stave Chapel at the top, camp is

halfway

Park at the bottom and walk up

Outhouse serves the Huckleberry Hill camp on

the left

Fire Circle and spring water faucet

We need to do something more..

Happy Camper

This is what we started with after the logging

project in 2018

That's Jordan Peak in the background

King Lake in the dip to the right

Square high quality granite blocks stacked along the

trail

Huckleberry hill is an unusual granite uplift that occurred after the

ice age.

The natural high shelf gives our doodle a great view

of the surrounding area